- A director from one of Romarm’s factories claims that the protective masks against coronavirus, manufactured under his supervision, are few and difficult to sell.

- The strategic investment for producing masks has turned into a governmental lie, says Cristinel Necula, a technical director at the Dragomirești Special Products Plant.

- There were major syncopes after the Prime Minister’s visit who had officially announced a production capacity of 350 thousands masks per day.

- In reality, at that time, the factory was producing only 15,000 masks per day, which is 20 times less due to the used equipment imported from China through an intermediary.

- The state risks losing the money they invested: the equipment contract was guaranteed by a non-banking financial institution (IFN) that was meanwhile unauthorized by the National Bank of Romania for numerous irregularities.

- At the same time, Romania has massively imported poor quality masks, which do not offer protection against the new coronavirus.

Ludovic Orban visiting the Dragomirești Special Products Plant on April 29, 2020. Cristinel Nicula (left) was the director of the factory. Source: The Romanian Government – YouTube screenshot

THE INSIDE MAN

“I will probably face more repercussions (because I spoke to RISE) but as I told you, I think it’s good for the truth to be known. More people will probably see that the truth is completely different than what has been said”, thinks the former general manager of the Dragomirești Special Products Plant, Cristinel Nicula

He says he was replaced on September 8, 2020 after the equipment purchased by Romarm for the production of protective equipment had syncopes and was stopped. Romarm is the national weapons and ammunition manufacturer but in the emergency and alert state situations, it joined the fight against the pandemic.

Cristinel Nicula is still a technical director and is aware of the current situation in the factory. He has been working at the Dragomirești Special Products Plant since 1986. First as a design engineer,head of a department, then he became a technical director. Later on, in 2014, he was appointed as a general director.

Dissatisfied with what happened to him, Nicula decided to talk about the plant he’d run for the past seven years. In an interview with RISE Project, the former general manager explains how the ones who questioned the masks production were removed.

THE TELEVISION REALITY

April 29, 2020, Dragomirești, Dâmbovița. Romania has declared a state emergency situation. Prime Minister Ludovic Orban visits the local weapons factory, accompanied by the Minister of Defense and Minister of Economy.

The government has invested here $1.6 million for producing masks, as a solution for the lack of sanitary protection materials.

So the workers from the Dragomirești Special Products Plant are now producing masks, instead of ammunition.

Pictured next to shiny metal parts, the Prime Minister inspects the new production equipment and everything seems to work like a Swiss watch.

Then, there is a press conference.

“Hello! I wore the first FFP2 mask, produced in Romania at the Dragomirești Special Products Plant, which is in fact FFP3 when it comes to the certification of the material that was used”, says Ludovic Orban smiling, while changing the surgical mask with a new one produced in the factory.

The Prime Minister is trying on a N95 mask produced at Dragomirești. Source: The Romanian Government – YouTube screenshot

The mask presented by the Prime Minister is the one that was recommended by the World Health Organization in medical maneuvers involving aerosols. The degree of protection offered by the mask reaches up to 95%, three times higher than that provided by surgical masks.

“The equipment was purchased for an automated production of these masks, with a capacity between 300- 350 thousand pieces per day for surgical masks. For the N95 masks, according to the European FFP3 standard, the production capacity will be between 70 and 75 thousand units per day”, adds the Prime Minister.

The factory was supposed to provide masks for hospitals and not only, because at the beginning of the pandemic, in February, the Government announced that at least 1.75 million FFP2 or FFP3 masks were needed for the emergency stocks.

THE REALITY FROM THE THE FACTORY

In the factory, things are different. Cristinel Necula, the former general manager says: „The machines were switched- on five minutes prior to the prime minister’s arrival, because there was the risk of seeing the parts all over the place. One machine was broken when he came. We were stunned by what he said on camera. We were making a maximum of 14,000 (masks) a day. How can you say that? I couldn’t take it anymore, the machines kept breaking down. It’s unreal! I think that night or the next day, the N95 machine broke down too.”.

Nicula also says that the day before, only 13,400 masks were made, more than 20 times less than what the prime minister had announced.

Director Nicula claims that the numbers stated by Ludovic Orban, i.e. 300-500 thousand masks per day, was said first by the Minister of Economy, Virgil Popescu. Contacted by phone, the minister explained that it was written in the contract.

However, Virgil Popescu claims after Cristinel Nicula was no longer the general director: „“suddenly, things started to work”, iar and the machines “did not function within optimal parameters but they didn’t break down anymore”.

But the equipment isn’t working now either, says Nicula, who adds that he informed the minister of the real production capacity five days before the prime minister’s visit.

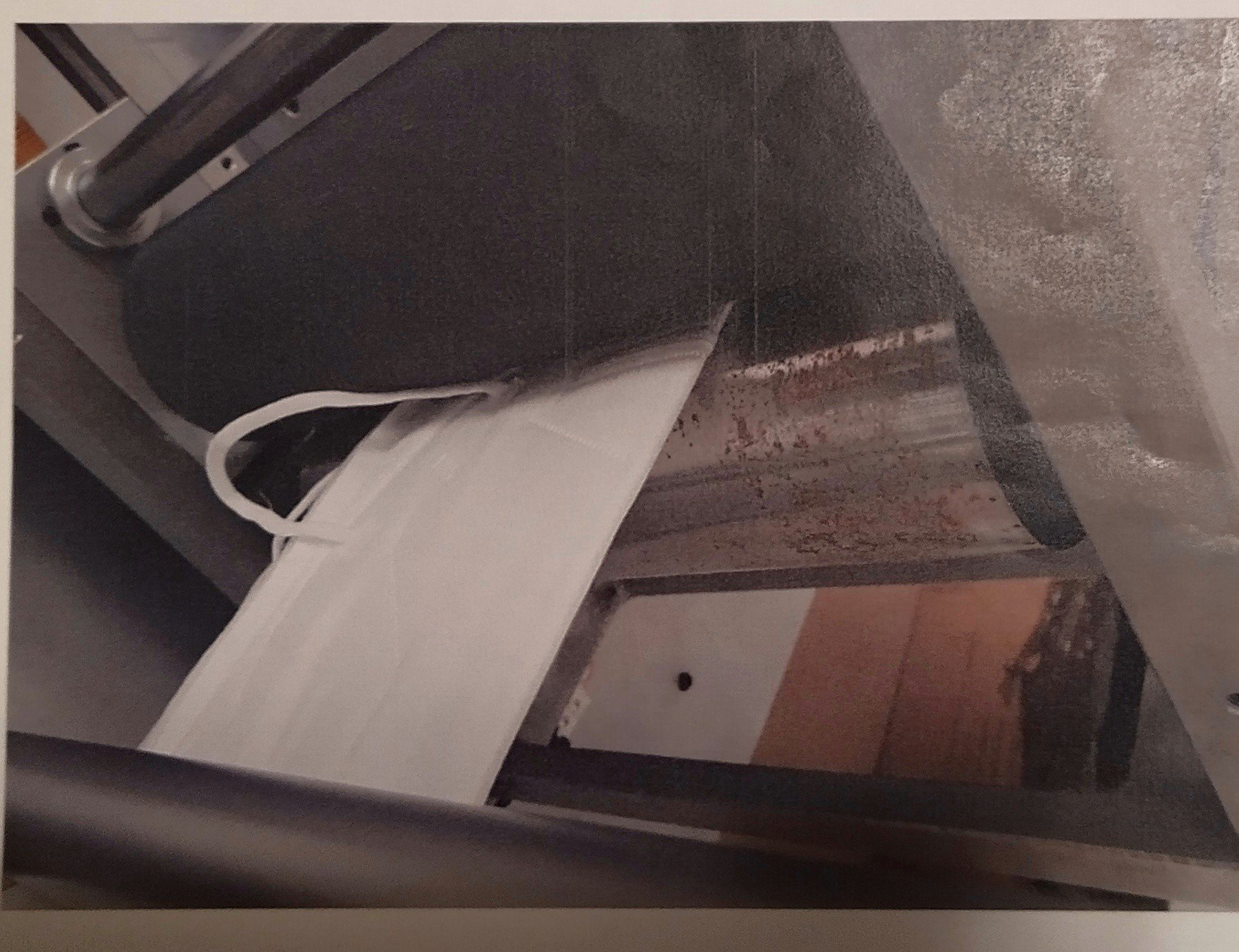

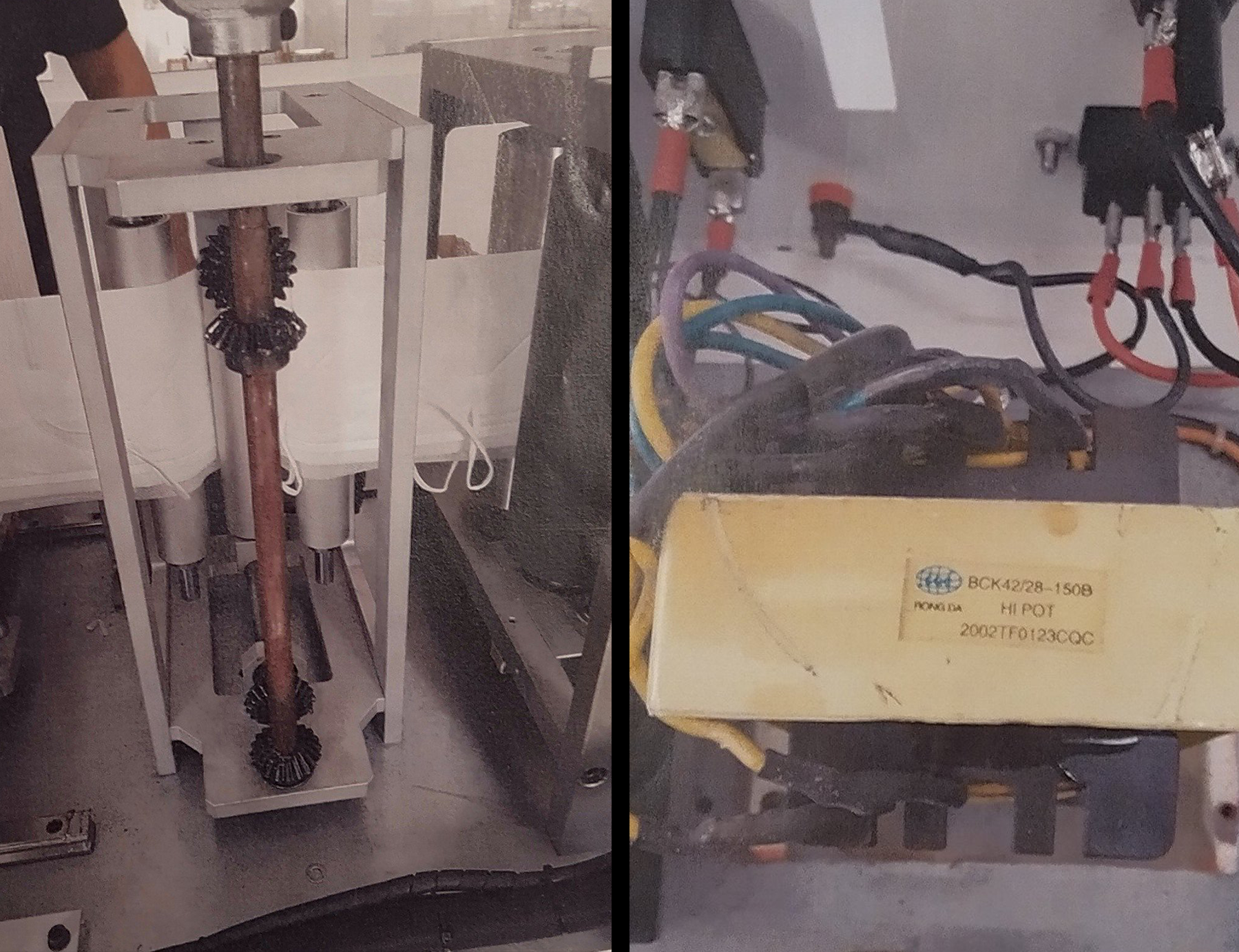

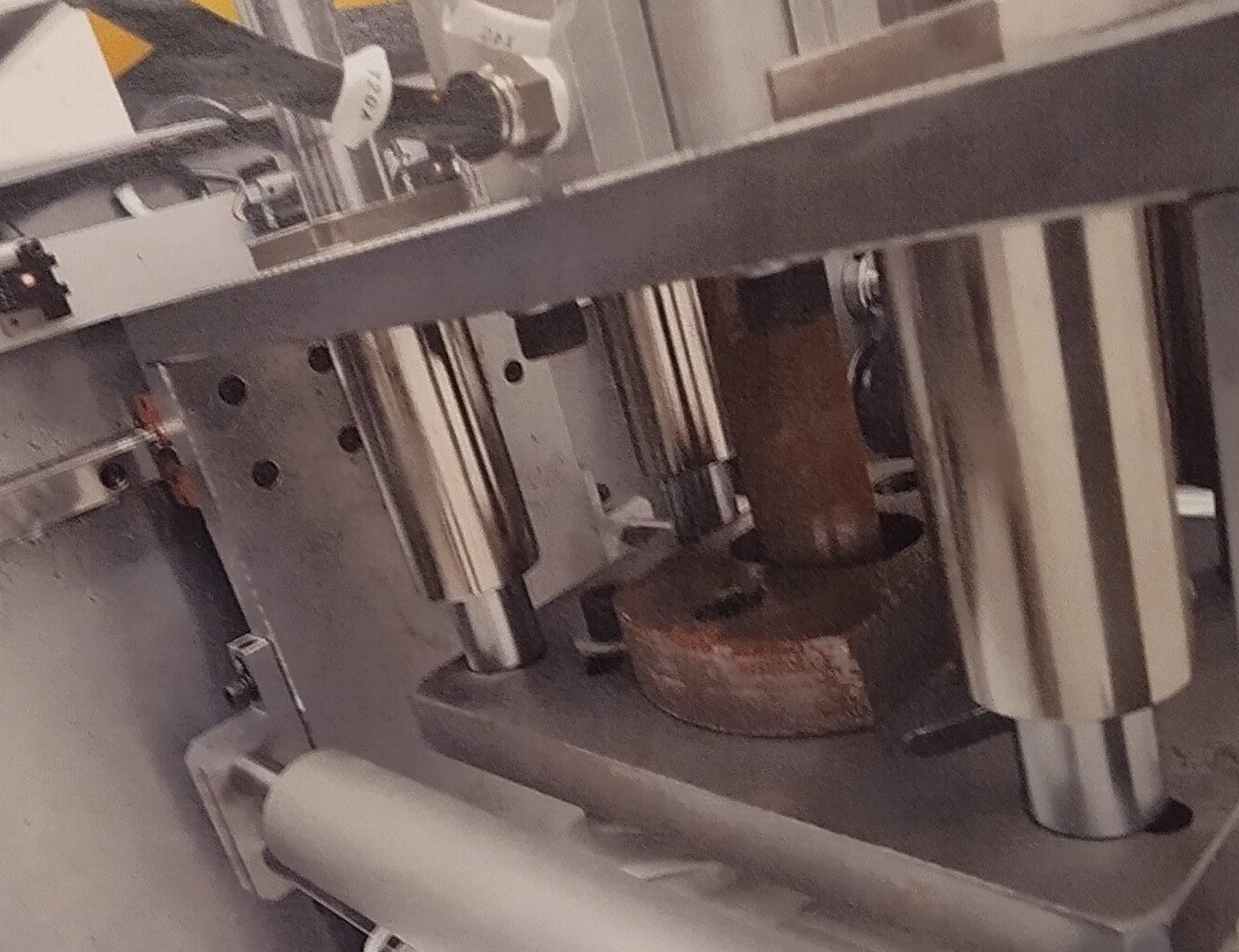

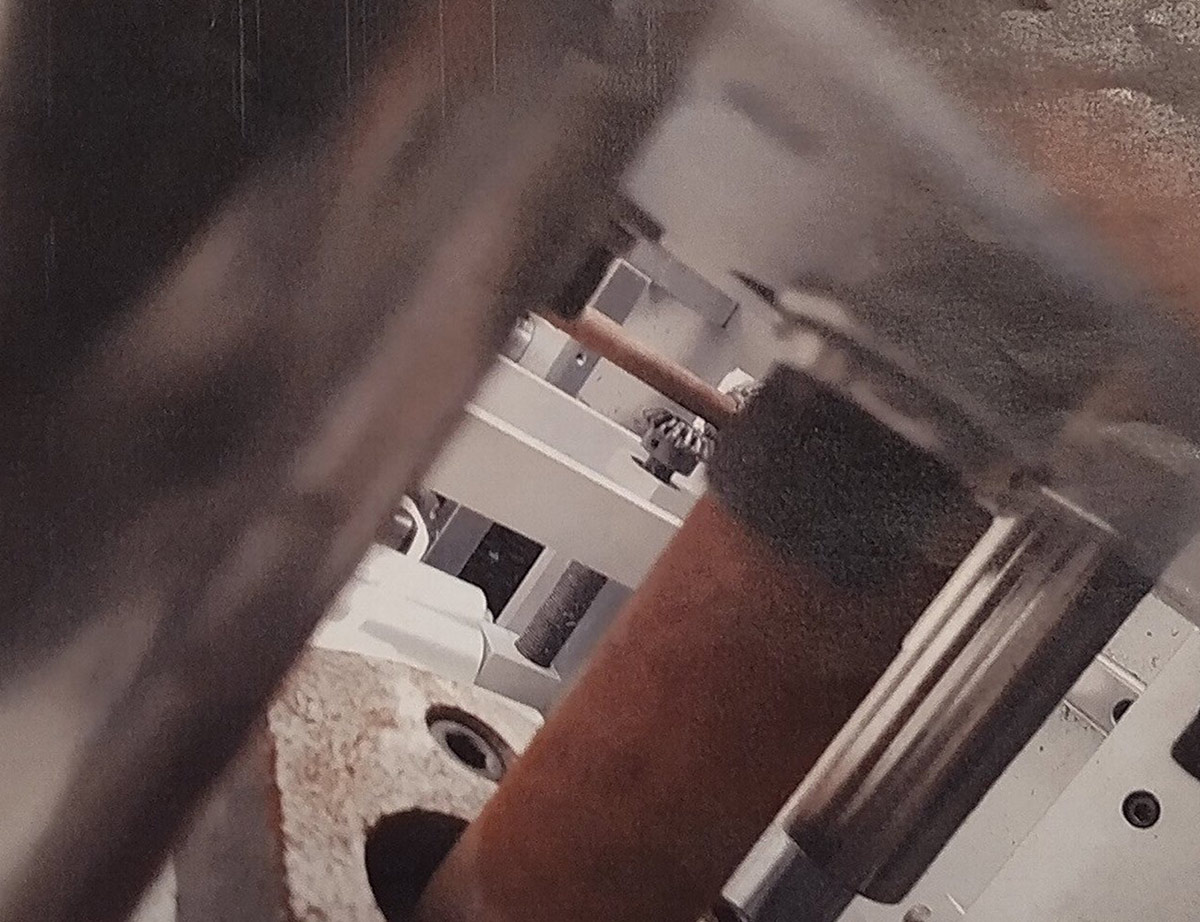

The photos taken inside the factory, obtained by RISE, show machinery with rusty parts used to produce masks that should protect us from coronavirus.

We showed images with a component of the production lines to Professor Corneliu Burileanu, PhD in electronics. “I don’t recognize the electronic components, they seem to be older than I am”, said the professor.

Prime Minister Ludovid Orban didn’t answer RISE Project’s questions by the time this article was published.

How did we get here?

THE OFFERS

March 24. Virgil Popescu, the Minister of Economy, announced that a state-owned company in the weapons industry will help fight against the pandemic: “I’ve had a talk with the director of Romarm and gave him the green light to start a production line of sanitary equipment, masks, medical overalls in Romarm, so that it remains in the strategic production of Romania.”

The next day, Gabriel Țuțu, the manager of Romarm, justified the investment of approximately 2.7 million dollars in equipments and materials for producing masks in a note saying that that the investment will be amortized right after the first month of production, if ten million surgical masks and one million N95 masks were produced.

Gabriel Țuțu (44) was appointed Romarm’s Manager in December last year and held several management positions in public institutions in the last 20 years.

He started working as an officer for the Romanian Secret Service in the early 2000s, while studying “Management of National Security Information” at the “Mihai Viteazul” National Intelligence Academy. In 2011, he worked in the cyber threat departament.

After that, he worked as an IT manager and advisor for the Romanian Lottery’s director, then

for the State Assets Management Authority (Autoritatea pentru Administrarea Activelor Statului) subordinated to the Government. He was also the vice president of FORTE Asigurări Reasigurări S.A, a company that went bankrupt.

The Financial Supervisory Authority (Autoritatea de Supraveghere Financiară) fined Țuțu with 50 thousand lei for favoring payments to people in close relationships with the insurance company.

At the same time, Gabriel Țuțu is an associate in two companies (Infoprimus Global Security SRL and Infoprimus Research SRL) with Ștefan Daniel Pirpiliu, former deputy in the 2008-2012 mandate, on behalf of PDL.

Țuțu is also a member of The National Association of Experts in Public and Private Security of Italy and also a member of The World Association of Detectives, according to the latest declaration of interests.

His life partner, Cristina Roxana David (44), has been a parliamentary advisor in the Chamber of Deputies (Camera Deputaților) since 2009. The following year, she became a member of the administration board of Romfilatelia SA, the institution designated to issue Romanian stamps and postal bills.

March 27. Romarm receives two offers.

Interarms Impex SRL offers to sell for 194,300 dollars, a machinery that produces eight thousand three layers masks per hour, and a price of 396,966 dollars for an equipment that produces N95 masks. The delivery time is set to 15 working days. Payment will be made 50% in advance, two days after signing the contract, 20% after checking the goods at the manufacturer, and the rest upon receipt.

The second offer was received the same day from AMP Synergy Bucureșt. The company wanted to sell machinery for producing three layer masks for 142,860 dollars with a capacity of 5,400 – 7,200 masks per hour. The delivery was to be made within 30 days, with a 30% advance. According to an email sent to Romarm, the firm said it will not make any profit because of solidarity. AMP Synergy associate, Ana Maria Popovici, declined to comment on the matter.

THE WINNER

March 31. Romarm signs the contract with Interarms Impex SRL, for the price of 979,866 dollars plus VAT.

Two days later, the company receives half of the amount, and after another four days, another 20%. The money comes from a loan taken by Romarm from CEC Bank.

Three production lines for the three-ply masks and one for the N95 will arrive on April 15, at Dragomirești Special Products Plant (Uzina de Produse Speciale Dragomirești).

Uzina de Produse Speciale Dragomirești was established in 1981. It currently operates under the national company Romarm. Workers normally make projectiles for Piranha transporters or F16 aircrafts, load thrower bombs, for aviation or artillery, and produce plastic explosives.

April 6. Romarm signs another contract with Interarms, of 728,450 dollars plus VAT, for production materials: elastics, metal strips for the nose, non-woven and filter material.

Interarms Impex SRL was founded in 2015 by an Italian citizen called Andrea Barsanti and was supposed to be active in the hotel industry. After one year, Michele Nusco and Nicola Meuli became shareholders too and the capital of the company rose from almost 50 euro to approximately 400 thousand euro and turned to trading, including weapons and ammunition.

Interarms imports Beretta weapons from Italy and in June 2019, Nicolae Bădălău who was the minister of Economy signed a collaboration contract with Beretta for producing assault weapons in Romania.

In December 2019, Interarms won five contracts worth 14.7 million lei with Sadu Mechanical Plant (Uzina Mecanică Sadu) which is also a factory under the Romarm’s umbrella.

Established in 1939 through royal decree, the plant had received money from the government for modernization, so it organized public auctions to buy new equipment for the production of ammunition. Interarms won the contracts, but never made any delivery.

Located on a side of the European road E70 Târgu Jiu – Petroșani, Sadu Mechanical Plant seems to be on the verge of an imminent collapse: the buildings at the entrance are damaged and employees warm themselves with air heaters

manufacturing of equipment for extraction and construction. Contacted by RISE, Perino Baranga, the majority shareholder, says he knows nothing about the auction or the Interarms company. Petal’s employees said the same thing. Baranga’s name appears in a criminal case of DNA prosecutors, in which the current PNL deputy Ionel Palăr was accused of taking bribes to appoint someone as head of Romsilva Bacău- a state authority that manages the forests in the area. The file has been closed.

Riccardo Barsanti, the manager of Interarms and the brother of the majority associate, has been investigated for poaching. In October 2009, the police found him together with another Italian, on a hunting ground in Tulcea, with 79 skylarks and 12 other wild birds, although they were only authorized to hunt ten skylarks. In the previous year, Riccardo himself had organized a hunt in which six other Italians took part, without having any authorization. The police then confiscated five rifles and hundreds of cartridges.

WARRANTY PROBLEM

The supply contracts between Romarm and Interarms are accompanied by a guarantee letter issued by a non-banking financial institution called Suport Real IFN. Theoretically, the document allows the state company to recover its money if Interarms doesn’t fulfill its contractual obligations.

But Support Real IFN, which was established in 2013, repeatedly violated the Romanian National Bank rules.Although it has the authorization suspended from August 2019, it issued the guarantee letters for the contracts signed by Romarm with Interarms.

A representative of the Romanian National Bank explained, without knowing the details of the purchase contract signed by Romarm, that “the guarantee that is not valid”.

Suport Real IFN SA has two companies as shareholders. One of them (Credit Burg) is owned by George Valentin Niculae and Gheorghiță Popa, who were sent to trial by the anti-mafia prosecutors in 2018, together with several other people, for being part of an organized criminal group. There is no final decision in this case.

The other company (PMB Intelligent Investment Grup) is owned by Marius Petre Bogdan and Alin Mihăiță Goga. The latter is a director at a company subordinated Bucharest Mayor House. He also worked for the National Road Company.

One of the IFN representatives is Radu Frîncu, a former director of the state bank Eximbank. In 2016 the prosecutors sent him to court because he spent almost one million lei of the bank’s money for vacations in Monaco, Ibiza and other locations. The judges have not yet ruled in this case.

The former director of the plant that was supposed to produce face masks, Cristinel Nicula claims there were people in Romarm who raised the issue of using the guarantee letter issued by the IFN, because the equipment was breaking down and not producing as much as it was written in the contract.

Nicula says that those people „were all slowly removed” , because they pointed out that the guarantee letter „did not have creditworthiness.”

During these months, Nicula felt he was unjustly being blamed. First, the plant was investigated by the National Court of Accounts

(Curtea de Conturi ), then by inspectors of The Minister’s Control Body who tried to make him guilty: “that some products that I approved are not in accordance with the standard, and that I am to blame.”

THE DELIVERY

April 13. The first trucks with equipment and materials arrive in Dragomirești in the evening, and the first problems already appear.

A reception committee finds that only three production lines have been delivered for the three-ply masks, instead of four, as stated in the contract, and moreover, they are not complete either. Power strips were missing. There are no technical specifications, declarations of conformity or documents that show the manufacturing year. What was delivered shows signs of usage. Everything is written in a report.

Former general manager Cristinel Nicula confirms: “The machines came without technical or assembly instructions and repair instructions in case of faulty. So we had absolutely no documentation, because it was actually stated in the contract that the machines will be put into operation by video with the Chinese who produced them.””

April 24. The rest of the components and the forth production line for the N95 masks arrive.

„“We were left with bundles of hundreds of cables that had to be tied to the rest of the machines. They made video conferences with the Chinese (n.r.: the producers). We tied them up but they didn’t work. Not even the Chinese knew how they needed to be tied”, Nicula explains.

The official visit of the Prime Minister then followed.

DEFECT AFTER DEFECT

Silence fell on the bomb factory turned to mask production until the end of May when reporters from a national televizion revealed that the production didn’t reach the level announced by the prime minister in Dragomirești.

Documents obtained by the RISE reporters show a long line of failures and problems.

REPEATED DELAYS

Although the contract signed at the end of March stipulates that the production lines had to be received within a maximum of three days from delivery, they have not been officially put to work until now.

The supplier, Interarms Impex SRL claims in the same document that the products are new and unused, and if the production lines do not meet the terms of quality, a replacement will be made.

But nothing has changed. The malfunctions became a routine and are recorded daily, for hours, in a register that has come in the possession of the RISE Project.

All of these because the director of Romarm, Gabriel Țuțu extended the supply contract through six additional contracts, with extended validity until December 2020. Some postponements are justified by communications with Interarms.

For example:

June 10 Interarms says the Chinese machine manufacturer cannot send a representative to help the Dragomirești Plant to make the machines work, “due to flight instability and the global situation.”

June 26. Interarms sends new documents to Romarm showing that the machines will produce fewer masks if they’re operated by inexperienced workers. That is between 4200 and 6000 masks per hour.

June 29. In another letter, Interarms accused the members of the committee, who refused to officially register the machines, of bad intention because the information made it to the press. It also blames the employees of the plant that they did not not use the equipment professionally, that they didn’t speak English and they refused the technical support that was offered. They have a solutions: to change the production location and the reception committee or to subcontract the masks production to a private company.

August 10. Interarms asks for a new extension: the spare parts arrived with delay and it’s the vacation season.

September 8. The supplier requests a new postponement, until December 2, 2020.

MADE IN CHINA

Interarms Impex SRL has so far received from Romarm 7,467,131 lei (1,684,281 dollars) for the equipment and production materials, through four payment orders.

The machinery and some of the materials needed to produce the masks came from China, and Interarms bought them from Sichuan Lingtong Intelligence Environmental Protection Industry Co. LTD.

The Chinese company was registered in 2016 and dealt with polluted water and solid or non-metallic waste until march 2020. It is owned by two Chinese citizens: Wang Ying and Liu Ruiqi.

According to documents obtained by RISE, Interarms bought the machinery with $ 710,000 – and received from Romarm an additional $107,423 at the beginning of April. It would receive another 163,486 when all the official documents were to be concluded.

The materials needed to produce the masks also generated other revenues for Interarms. For example, the company bought melt-blown from an Italian company called Ramina. It paid 20 euros per kilogram and sold it for 59 euros to Romarm.

The equipment was transported into the country by the Swiss company Allodium SA, which according to a document obtained by RISE Project, had an agreement with the Interarms.

Invoice value: $316,000.

Allodium SA was registered on May 30, 1996 and is headquartered at Goldblum and Partners, a law firm in Zurich, “the heart of the Swiss tax haven”, as it’s written on their website. The shareholders of the Swiss company are hidden.

In 2012, Allodium was investigated by the Ukrainian secret service, after signing contracts for transportation services with UKRSPETSEXPORT – a state-owned company in Ukraine, which deals with import and export of weapons. In September 2015, the case was sent to prosecutors in Kiev. In the meantime, Allodium continued to sign contracts with the same state-owned company in Ukraine. The investigation is not yet closed.

The price paid for equipment and materials includes also the costs for delivery. The transport was evaluated at $ 370,800 (i.e.,170,800 for machines and 200,000 for materials). However, Interarms had the right to request extra money and that is exactly what it did: it received an additional $ 57,724 from Romarm.

THE BOXES

In June 2020, Romarm bought 109,440 boxes for masks from Tipomar Packaging SRL, a company registered in a city near Bucharest.

The company is owned by Emil Marius Marinescu, the husband of Simona Elena Marinescu- who works for The National Office of Secret Information (ORNISS), an institution that, among other things, issues certificates of access to secret information, that those in the defense industry must also have.

Simona Elena Marinescu is an engineer and has worked at ORNISS since 2004. She is now Deputy General Manager in a department that manages the accreditation processes of computer systems that manage classified information.

Her husband’s company, Topimar Packaging SRL, has received from public institutions over three million lei of public money during 2007-2018. Most contracts are direct assignments and the biggest are with the state institution she works for.

For example, in January 8, ORNISS also bought from Tipomar Packaging non-counterfeitable printers, worth 129,200 lei.

THE MASKS

The Dragomirești Plant has produced almost four million masks in eight months. We asked Romarm and the Ministry of Economy to give us access so we can see the production lines and the mask stock. When we arrived in Dragomirești, we were granted access only to the mask stock, not to the equipment as well. The reason for refusal: we needed a special permit to enter the weapons factory.

We then applied for the access permit twice, but we didn’t receive it up until today. We only saw dozens of boxes with masks, stored in a building near the factory gate. There was a CE marking on the boxes, but the batch number, date of manufacturing and of expiry were not mentioned, as they should have been.

The former director of the plant, Cristinel Nicula claims that the masks don’t have all the necessary certifications, precisely because the equipment has not officially been put into operation. A certificate of conformity that accompanied 5,200 masks delivered to Tohan Zărnești SA (another factory subordinated to Romarm) in July, shows that “the products were obtained and inspected during tests and trials performed for the mask producing machines.”

Therefore, without certifications, the masks are distributed mainly on the Romarm circuit, not helping the doctors in hospitals.

THE REACTIONS OF THOSE INVOLVED

More than 60% of imported medical equipment doesn’t protect against the pandemic infection. They are non-compliant. It was discovered and announced a week ago by the Consumer Protection Office, which also notified the General Prosecutor’s Office.

The Minister of Economy, Virgil Popescu then commented on the situation discovered on the mask market:

“I am disappointed with the quality of the face masks on the market at the moment. If I tell you that half of the masks currently on sale in distribution networks – hypermarkets, pharmacies, warehouses, importers – do not protect us, you’d say I’m exaggerating but that is the reality. I want to send a very clear message: this must stop. We can’t accept the sale of masks that do not protect the population.”

Non-compliant masks have also reached hospitals. In October 2020, Romania registered 3,847 coronavirus-infected medical personnel and 33 deaths, according to the Ministry of Health.

In the first six months of the pandemic, more than 2,500 tons of medical or protective masks were imported and sold to us, without anyone checking the safety standards.

The Romanian state lost eight months in which it could have produced millions of masks in Dragomirești for the strategic stock still necessary in the fight against the new coronavirus.

RISE Project contacted the actors involved in this failure.

The Minister of Economy, Virgil Popescu, suggested that two employees from Dragomirești allegedly sabotaged everything – “It was noticed that (…) the settings were being modified” – și and claimed that the masks produced in Dragomirești are authorized and comply with the European commercial standards.

Ministry of Economy – Virgil Popescu. Photo: INQUAM / George Călin

But Romarm obtained a commercial authorization from an army structure, designated by the Government, a different procedure than the one necessary to obtain the right to apply the CE marking, which involves an independent body to test and certify the quality.

Regarding the invalid guarantee letter, Virgil Popescu declared: “I exclude any fraud possibility. There are malicious voices, but this is something else” and he emphasized that the National Romanian Bank sent the confirmation to Romarm that the guarantee is valid.

“The purpose is to have this capacity (to produce masks), a functional capacity. Obviously there will be penalties, obviously the supplier will have to pay because they were not put into operation when they should have been. (…) Don’t believe everything that is being said. I’ve learned over time that the truth is in the middle”, said the minister.

He added that Interarms recently bought some more production lines at Dragomirești to ensure the production capacity written in the contract.

Alin Goga, associate and administrator at Suport Real IFN, explained the suspension decided by the Romanian National Bank: “I tell you openly. There is a competing company, in this case called Pro Capital which gave a bribe of two million euros so they can close us, because we were the main opponents. We will win this one in court.”

Radu Frîncu is still listed as the administrator of the IFN but Alin Goga claims something else: “we’ve separated a very long time ago, due to reasons of ethical incompatibility.”.

A representative of the Swiss company Allodium SA, with hidden shareholders, that was in charge of transporting the goods from China, told us by phone to come back after an hour. Then, the answer was dull: “We can’t give you any information”.

Gabriel Țuțu, the director of Romarm, initially asked to see the questions before the interview. Then, during the meeting we had on August 24, he asked the RISE Project reporter to sign an agreement in order to be recorded. This didn’t happen.

He said that the equipment was brought to the country with the company of the Ministry of Defense from Ukraine, and admitted that it was not received, nor officially put into operation because it was not in parameters.

“The machines never stopped (…). There were syncopes, various parts broke down, we had to replace them with more solid ones. These types of situations happened. (…) Only one machine had long term issues”, said Țuțu.

Then we wanted to clarify some of the aspects, but Gabriel Țuțu did not answer the phone.

Riccardo Barsanti, Interarms Impex SRL,claimed that the equipment came to Romania with the help of the Ukrainian air force, through Allodium SA, and doesn’t know who is behind the company. The equipment for mask production “was delivered with installation instructions and wiring diagrams” and “does not comply with the parameters of the technical specifications, but is functional. They have broken down from time to time”.

Regarding the guarantee letter issued by the IFN, Barsanti said “at that time, they were registered in the BNR register”.. He also mentioned that in the meantime, it has been transferred to another IFN.

„“A political article. It’s a paid article”, said Riccardo Barsanti at the end of the phone conversation with the RISE Project reporter.

The Chinese manufacturer didn’t respond to our emails.

Until yesterday, December 4 2020, Romania registered 500,273 confirmed cases and 12,052 deaths caused by the new coronavirus.

*This article was partly funded through the ”COVID Beneficiaries Platform” project, run by Stanford University Journalism Fellowships in the United States (John S. Knight Fellowships and Big Local News, funded by the Google News Initiative).

*This article was partially funded by the Friedrich Naumann Foundation for Freedom Romania, which is not responsible for the content of the article. The opinions expressed exclusively belong to the authors and do not necessarily reflect those of the Friedrich Naumann Foundation for Freedom.